As simple as changing a non-stock key code or selecting a non-standard finish, all the way to a completely new lock design, uniquely developed to meet your needs. Custom solutions can potentially save money, while enhancing the value.

- Stamping, coining and overmolding customer company logo on keys

- Restricted and registered key codes

- Custom packaging

- Custom designed electronic membranes (using customer logo and colors)

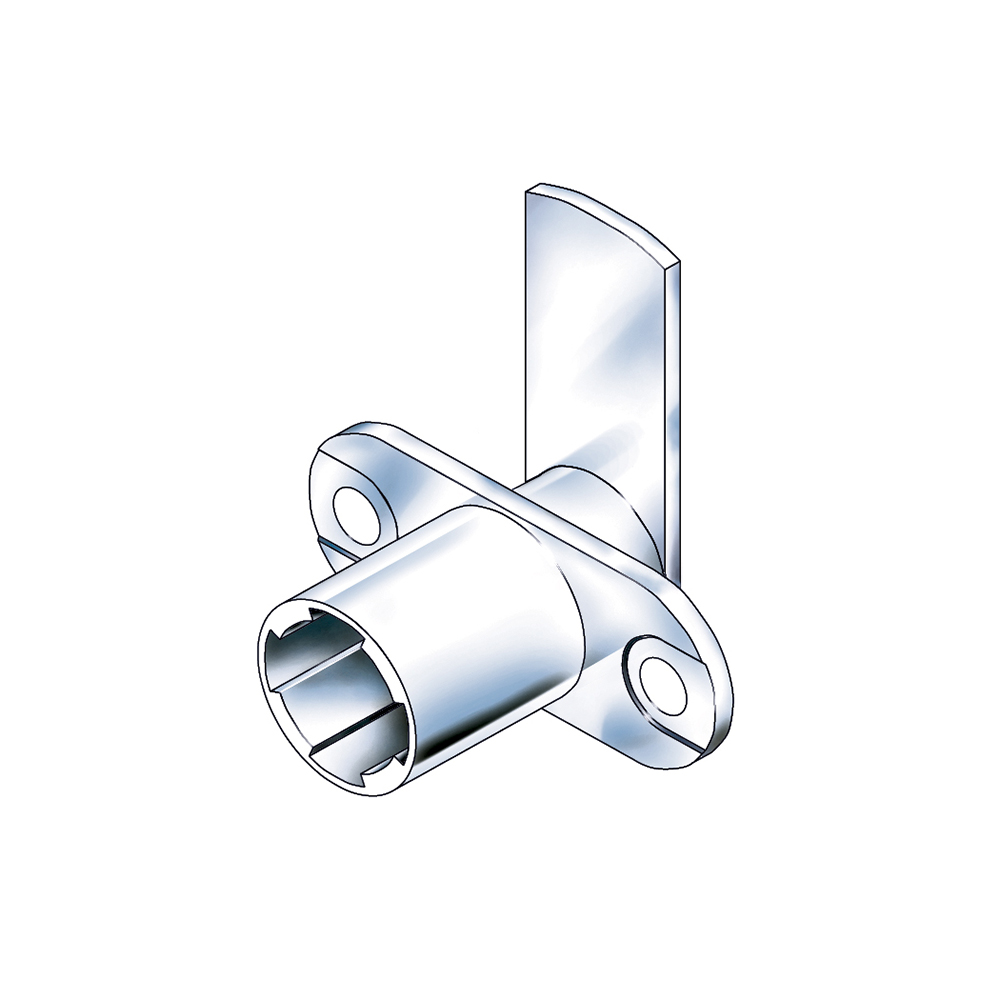

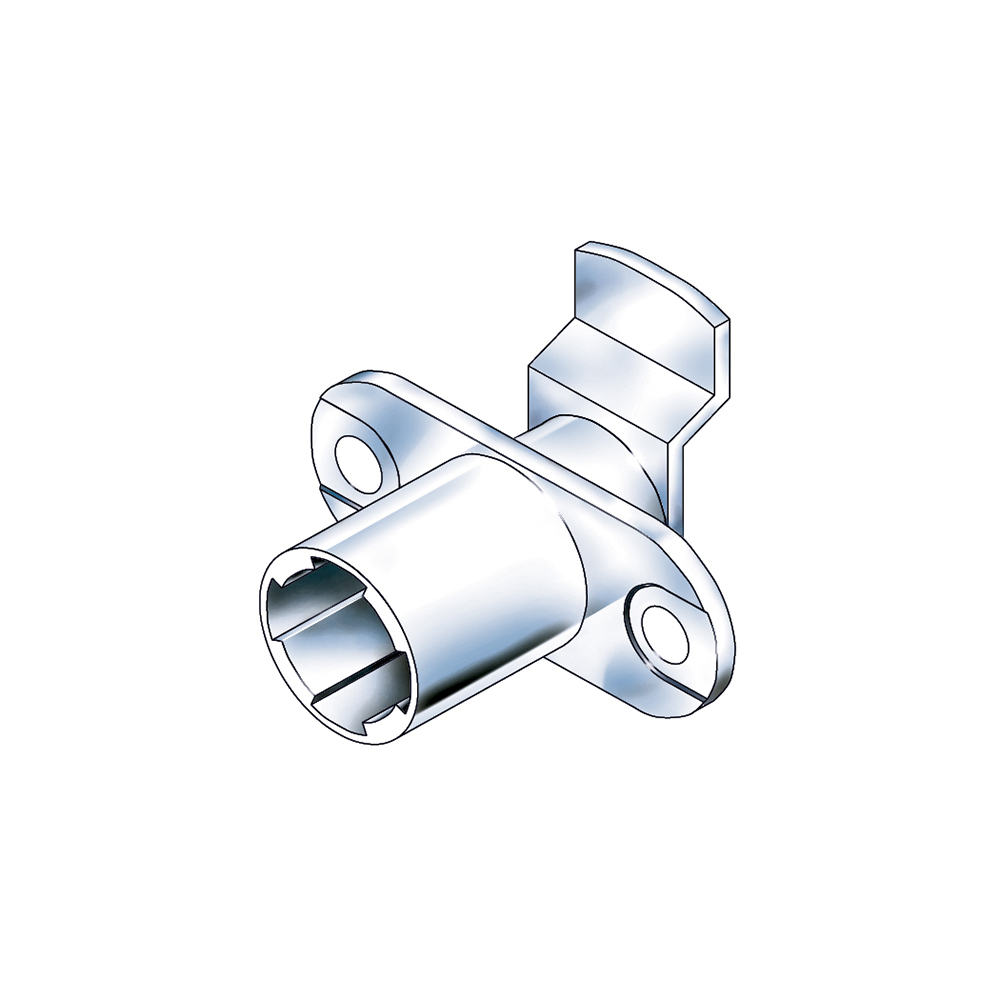

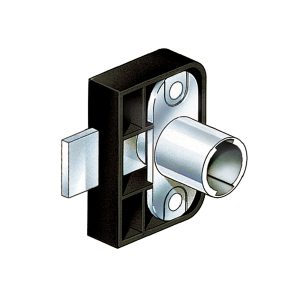

- Custom latching: cams, bolts, etc.

- Additional codes and master keying levels

Capabilities

CNC machining

CNC turning centers allow cost effective solutions for non-tooled components or specialized applications.

Zinc die-casting

State of the art miniature / medium hot chamber die casting machines allow great part flexibility with simple mold inserts.

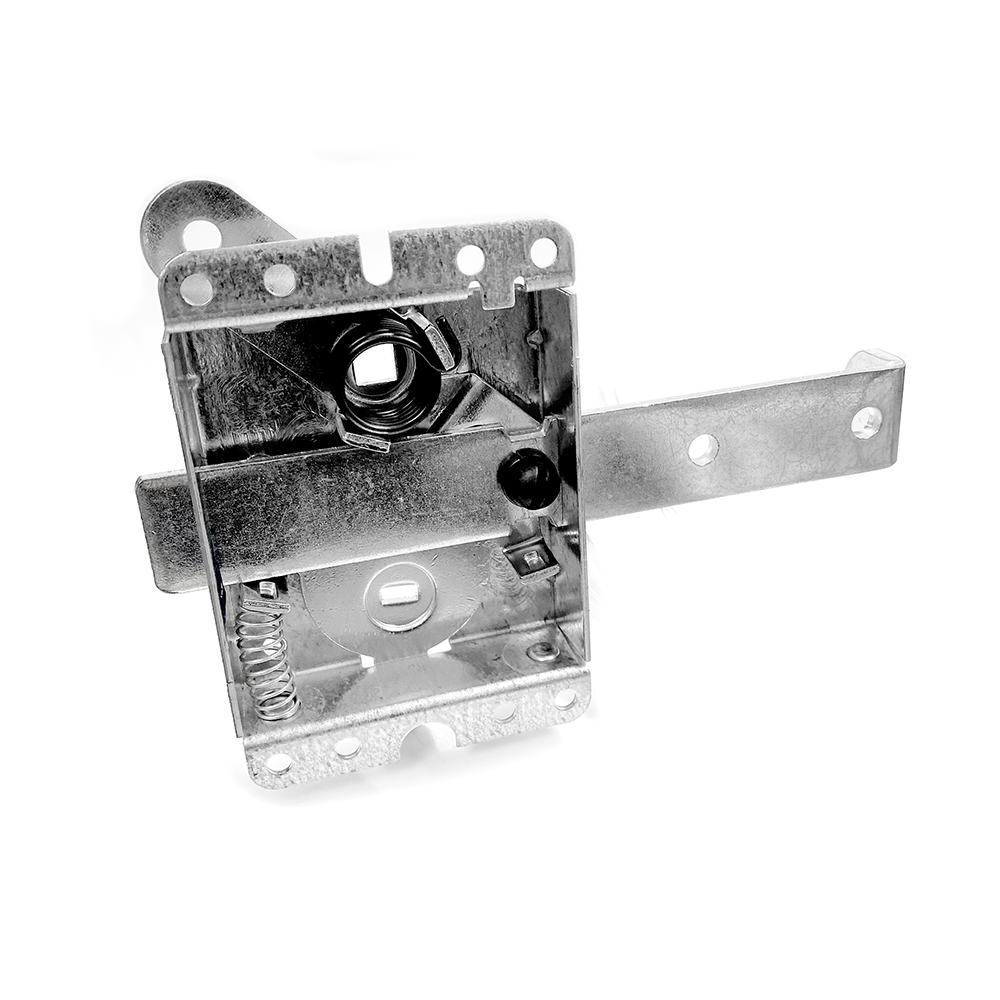

Metal forming and stamping

CompX uses stamping presses to punch and form components and press brake systems to form sheet metal to exact customer specifications.

Laser cutting

For sheet metal processing, our team has you covered. The Bystronic BySmart Fiber Optic Laser 3015 can accommodate sheet sizes up to 118″ X 60″.

Wire harness

Flexible workcenter making a variety of harnesses, pigtails, and sub-assemblies to support electronic and custom applications. Capabilities include: Wire straightening and stripping, semi-automated termination, soldering and testing.

Tube and pipe bending

Precision tube end forming can be accomplished through single or multiple hit end forming or rotary forming devices on small-to-large diameters.

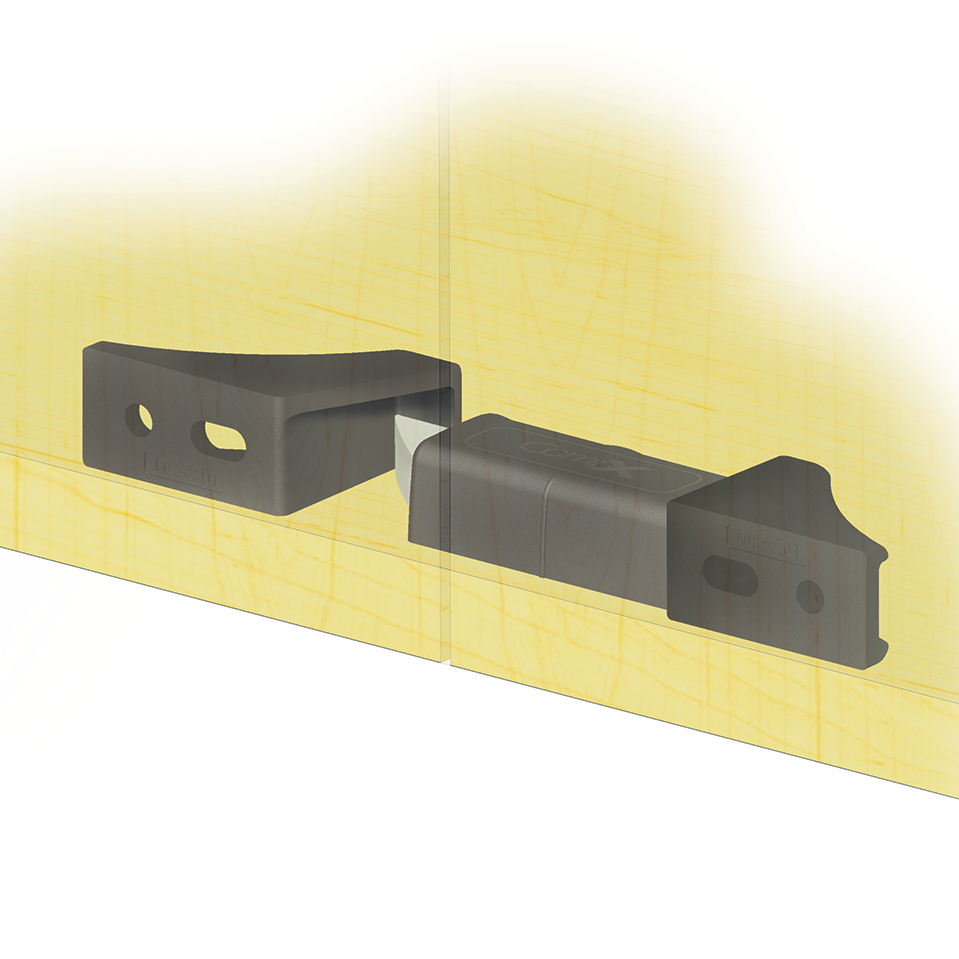

Injection molding

Customize your products with your own branding on overmolded keys.

Plating finishes (chrome, nickel, zinc, brass)

CompX has the most advanced, environmentally friendly rack, barrel & continuous plating lines with fully equipped laboratories and professional staff to support finishing processes.

Powder coating

Color match existing schemes using our custom color application process

Assembly

State of the art manufacturing cells allow greater product flexibility and lead times, assures the highest levels of quality, while maintaining cost competitiveness. CompX continues to invest in our people and manufacturing methods to meet and exceed our most demanding customers’ expectations.

Primary Raw Materials

- Brass

- Zinc

- Stainless steel

- Cold rolled steel

- Aluminum

- Engineered plastics

Primary Products

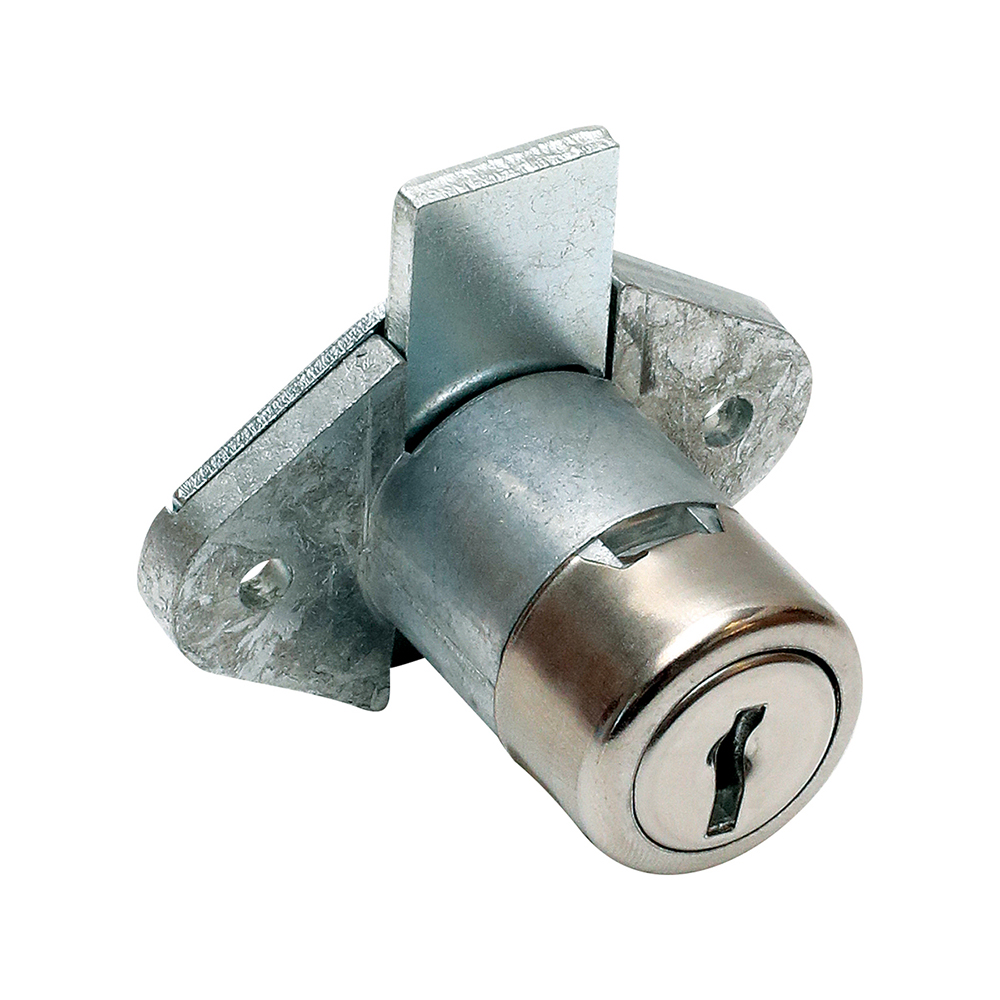

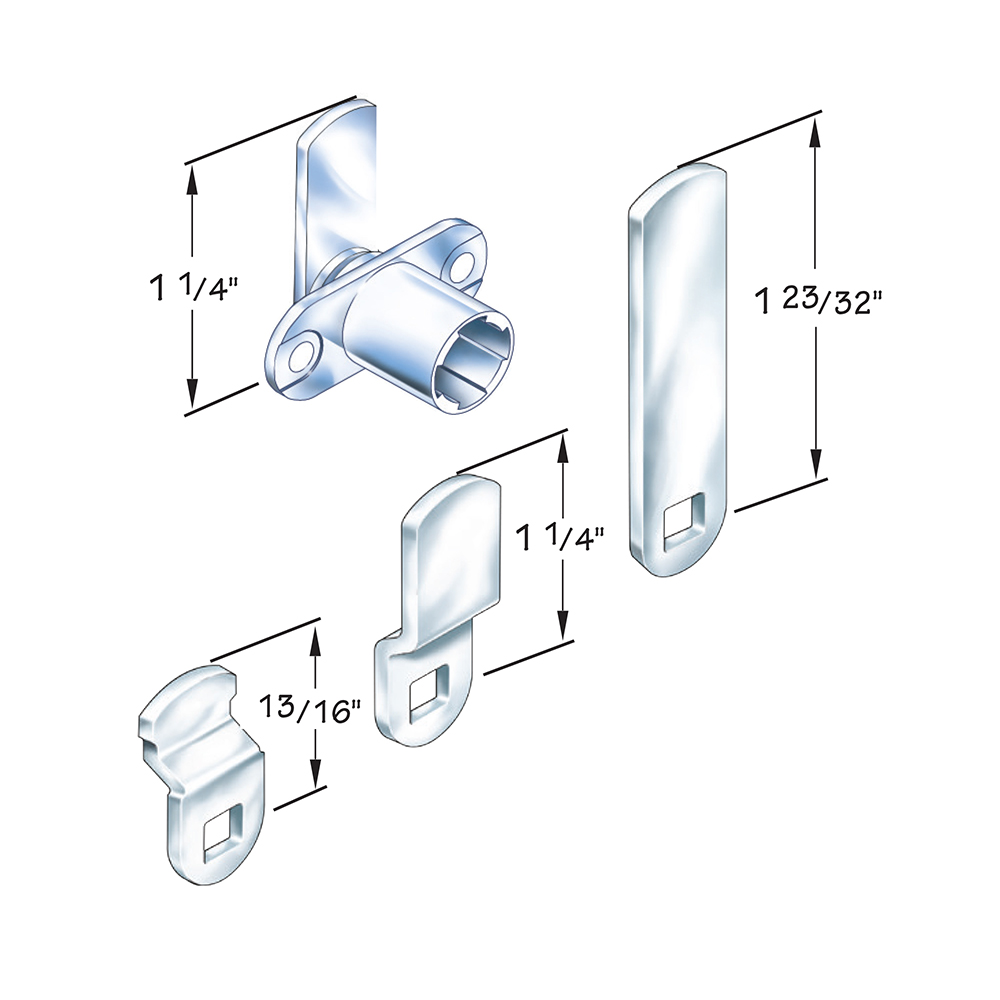

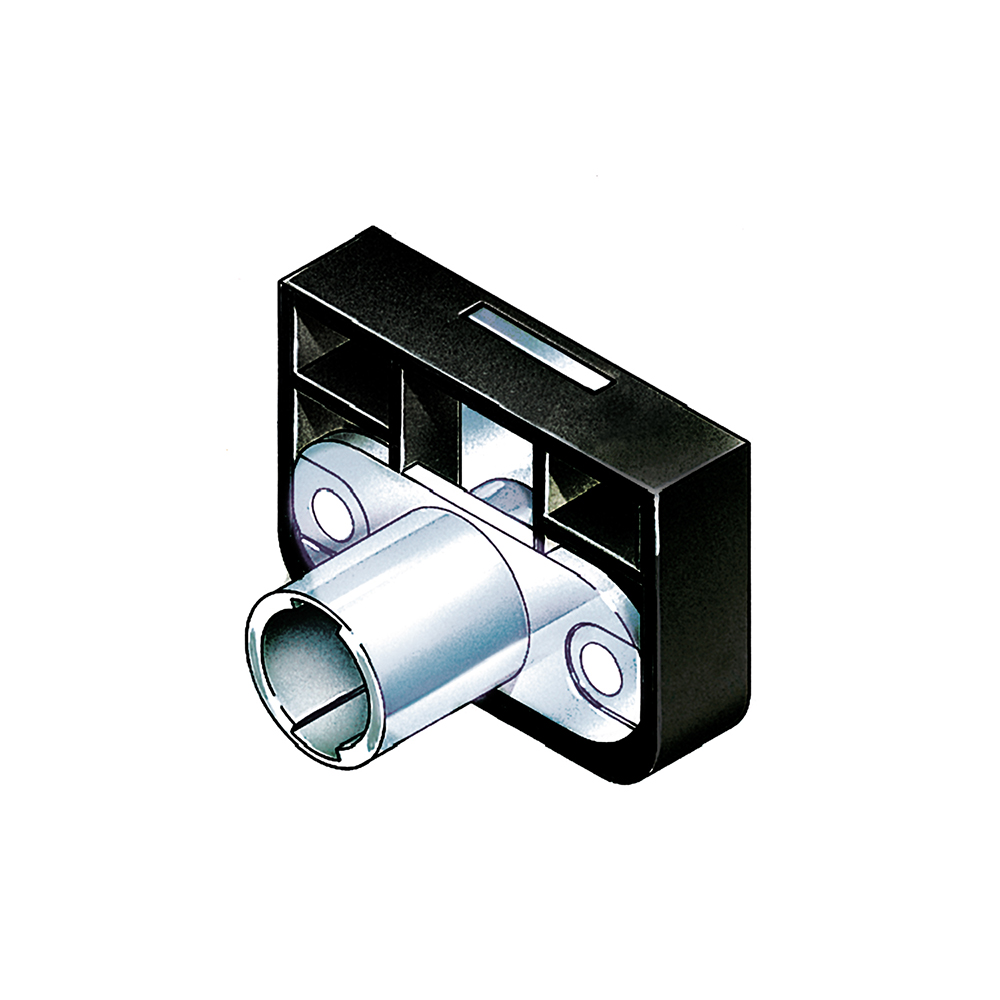

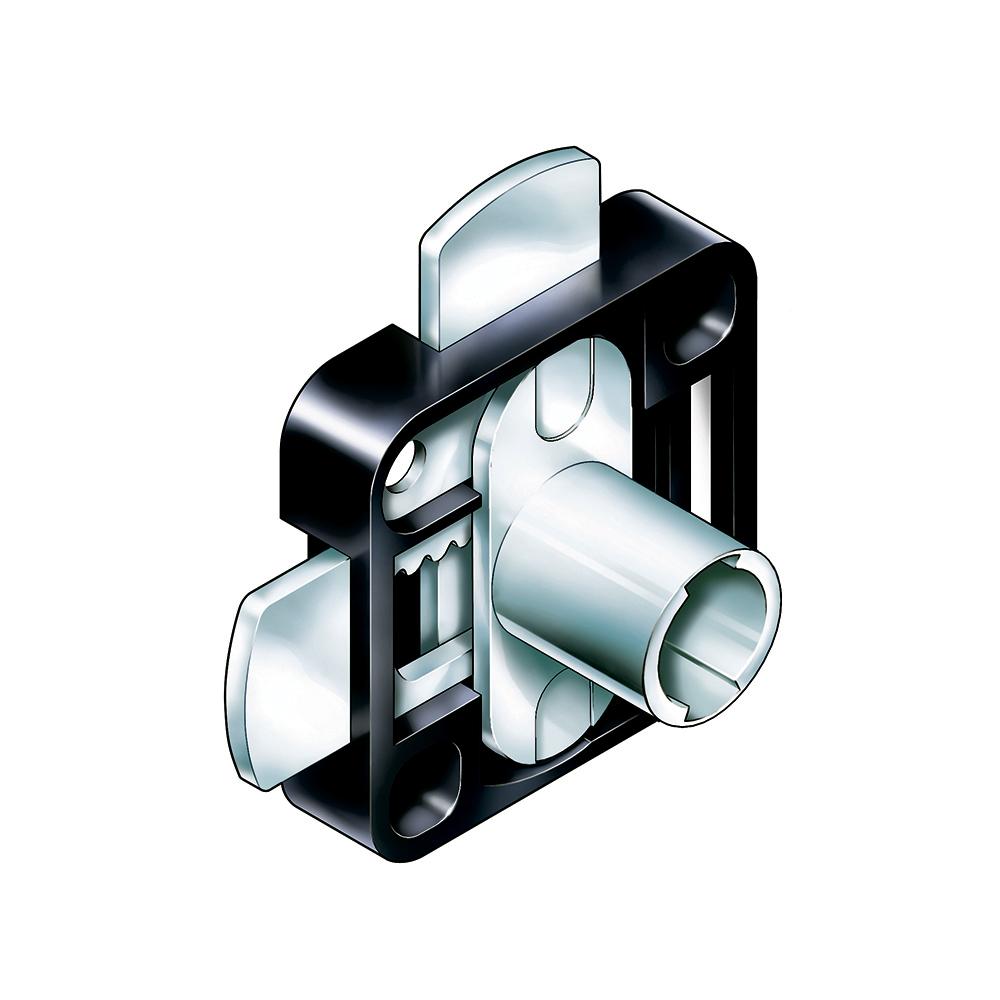

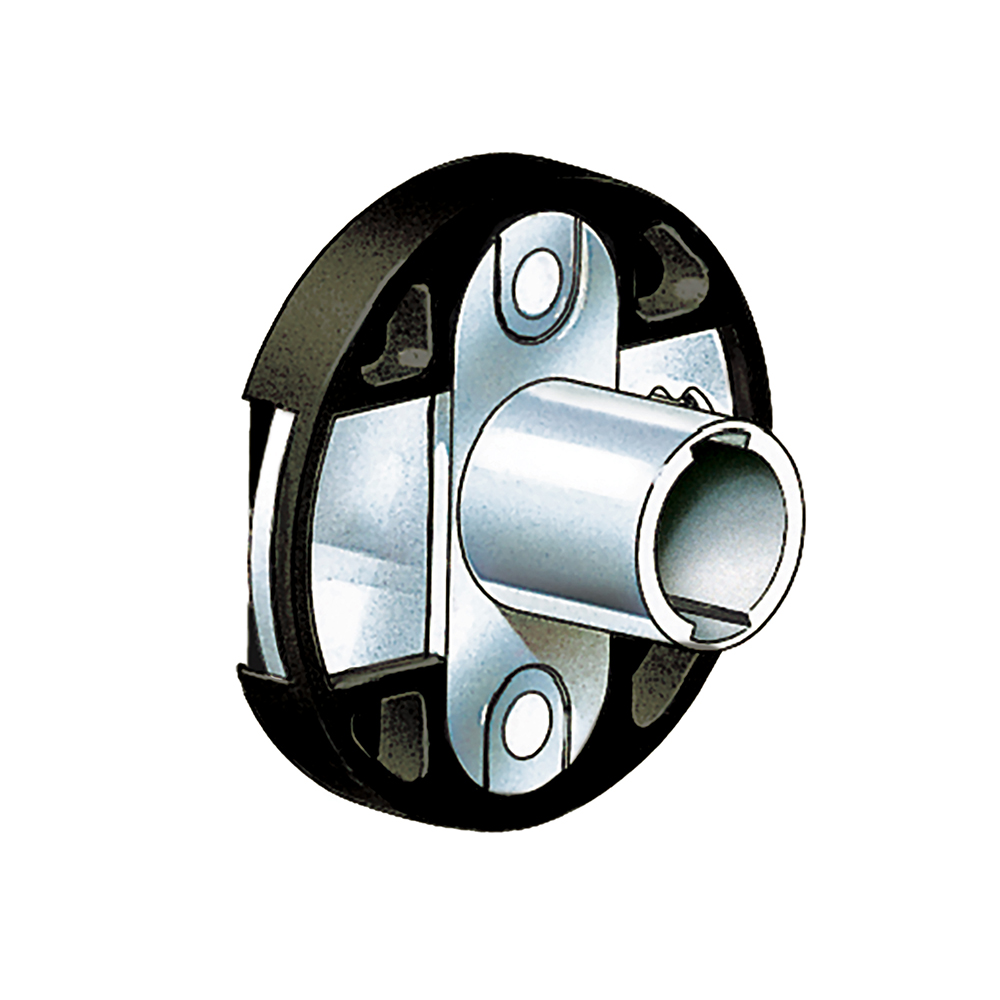

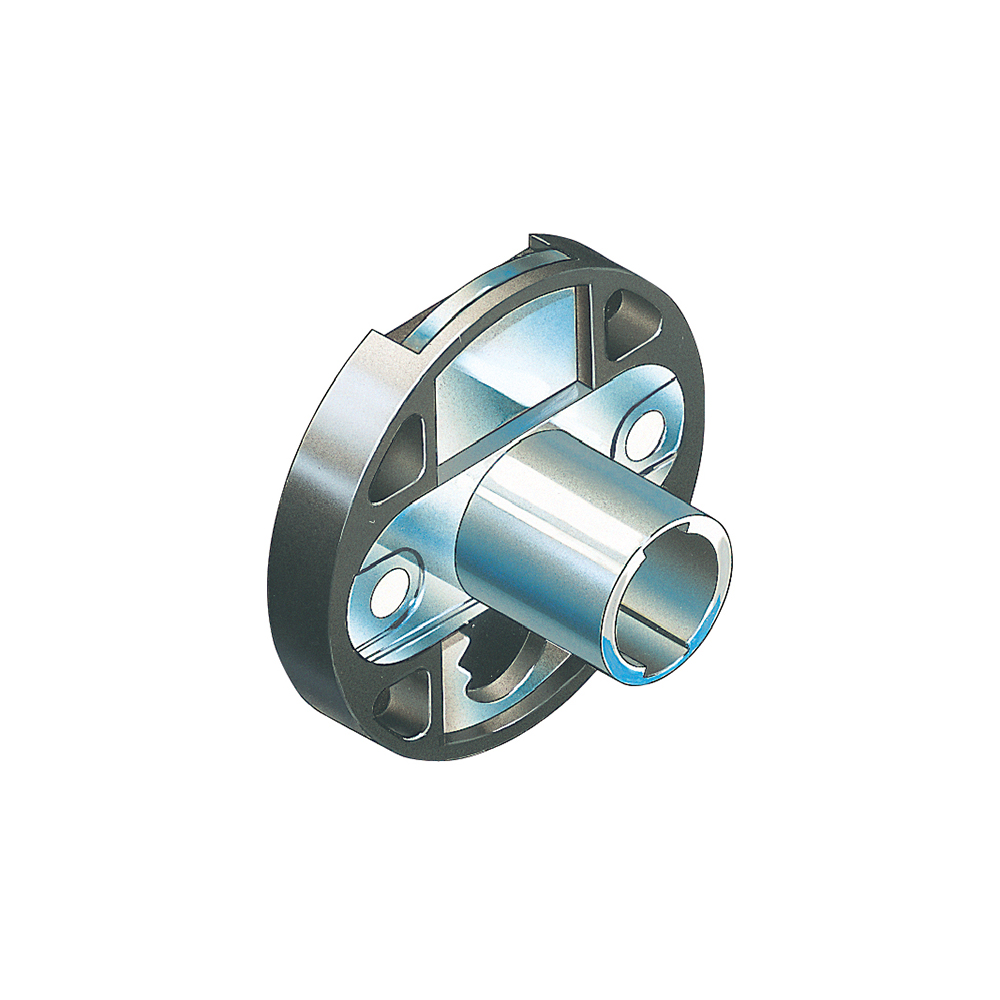

- Cam locks

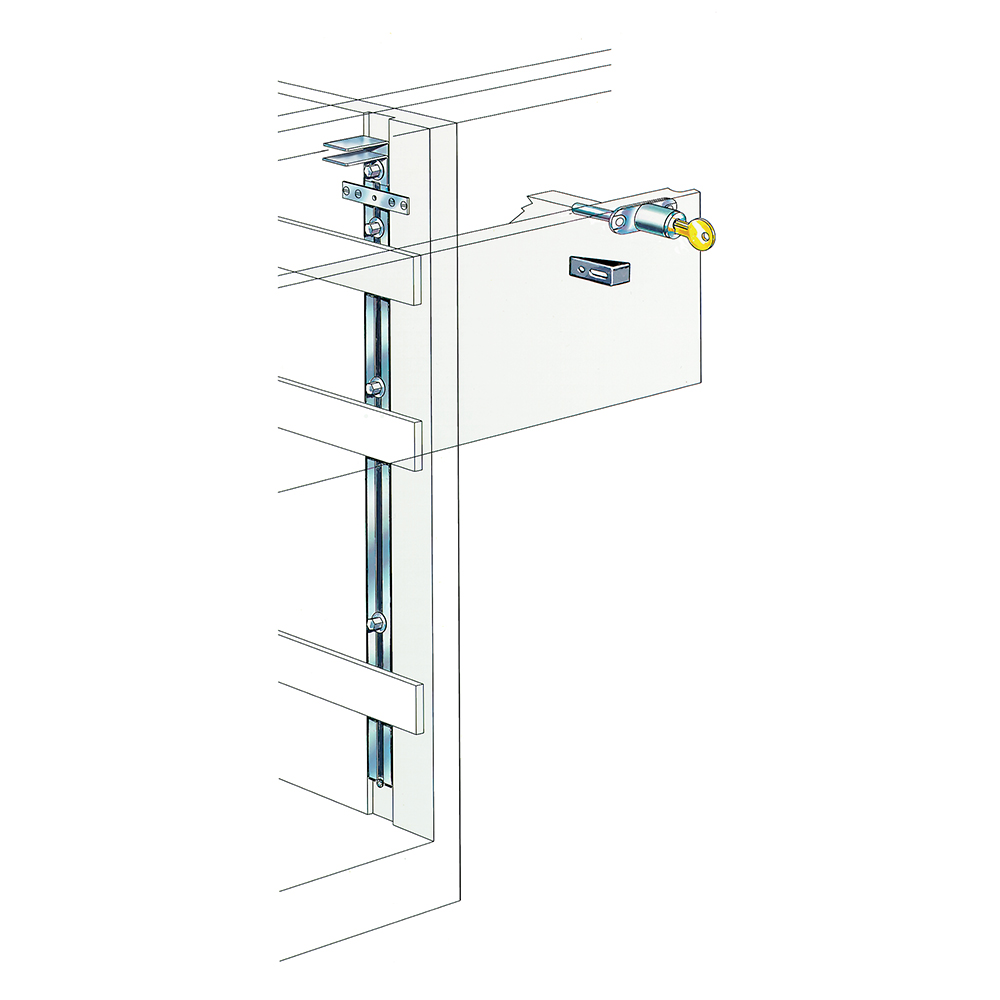

- Bolt locks

- Low, medium and high security options

- Handle locks and latches

- Electronic locks / access control

- Keyless locking products