Architects

CompX works closely with architects to help specify the appropriate domestically made cabinet lock(s) for projects, from K-12 schools to healthcare facilities, and beyond. In an effort to help educate and to support the continuing education requirement for architects, CompX developed two classes – both fully approved by the AIA – about cabinet locks.

Continuing Education

Two AIA approved Continuing Education courses from CompX:

- Introduction to mechanical cabinet locks = 1 LU credit (course # AIACES2023-M)

- Introduction to keyless access control for cabinets and other enclosures = 1 LU/HSW credit (course # AIACES2022)

CompX has dedicated Architectural Specification Reps, available to help with project planning and specs. Contact CompX for help or if your firm would be interested in hosting a Continuing Education course.

Engineers

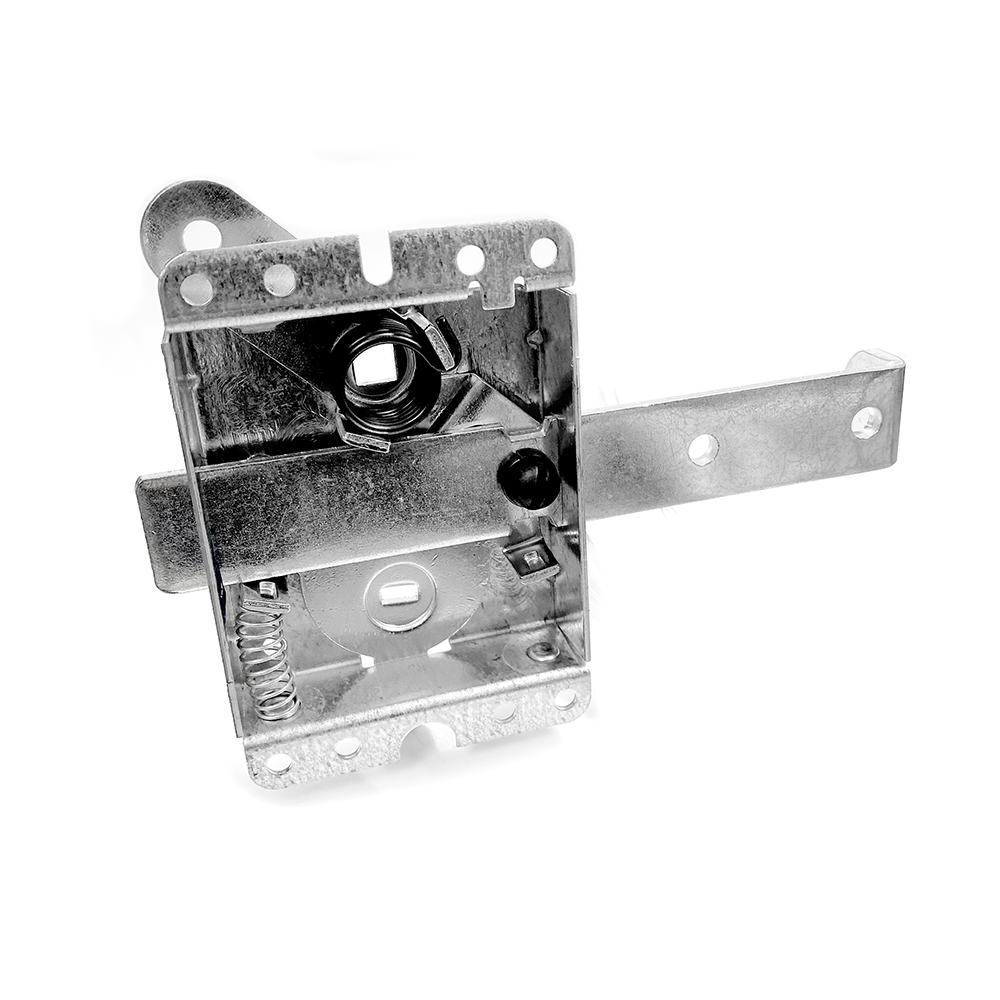

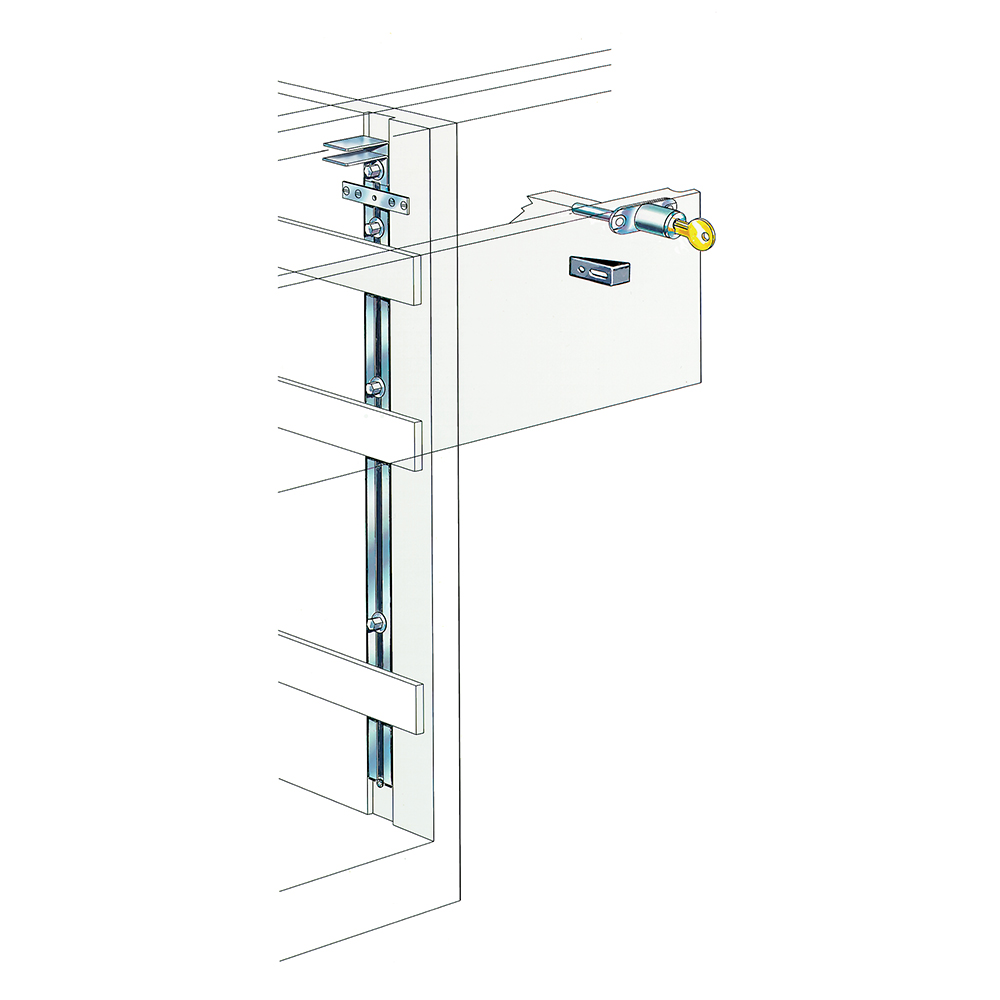

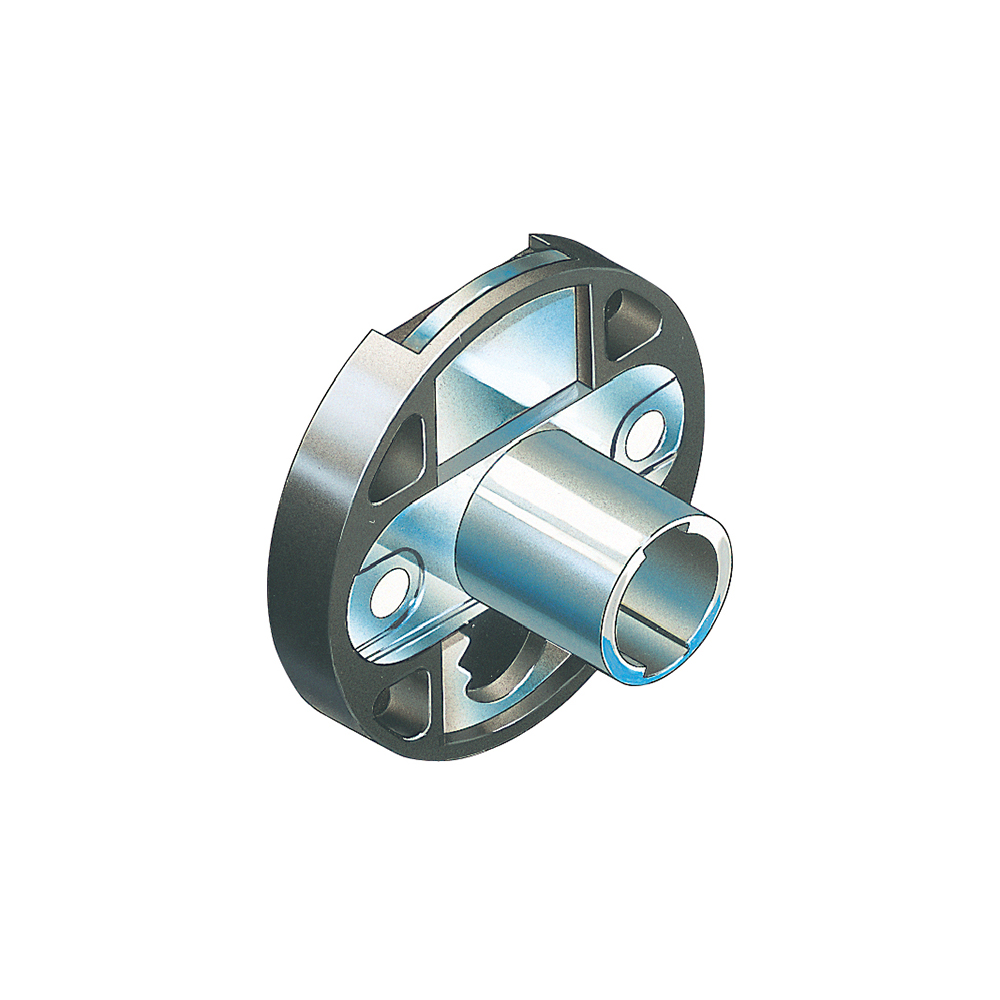

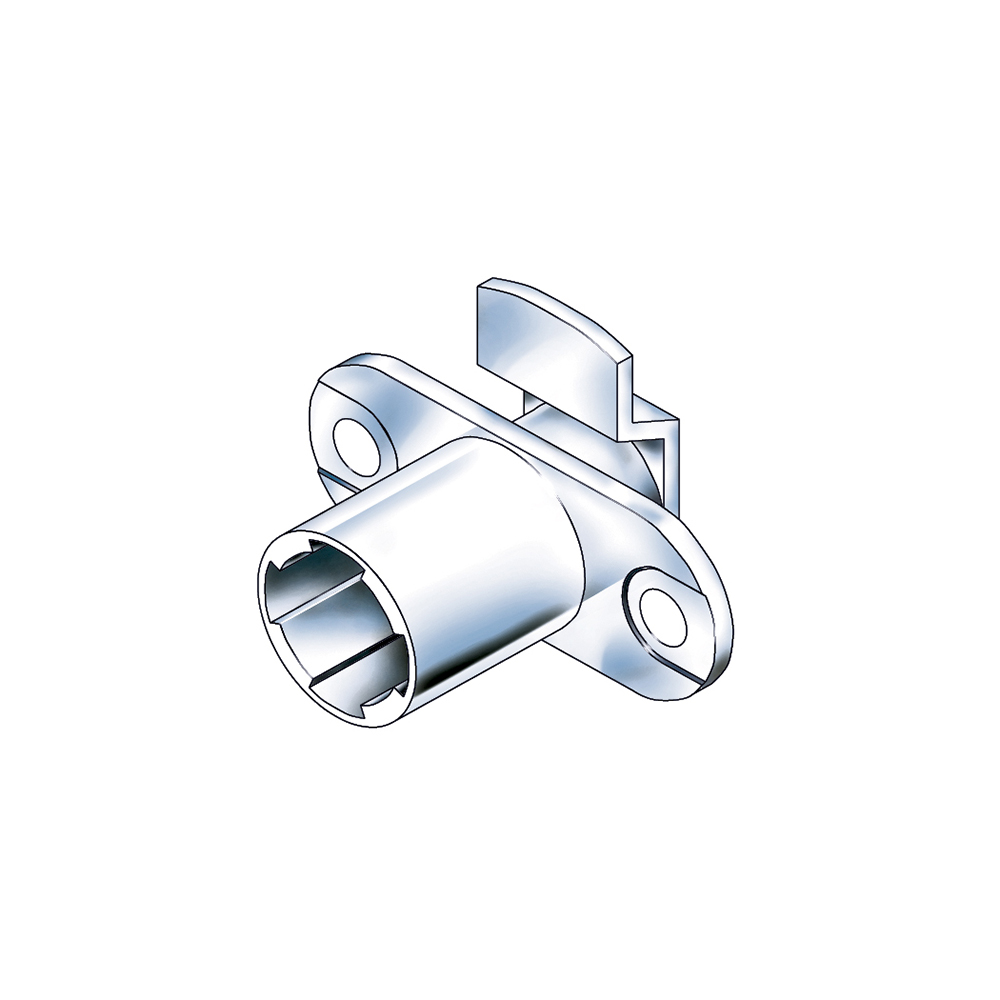

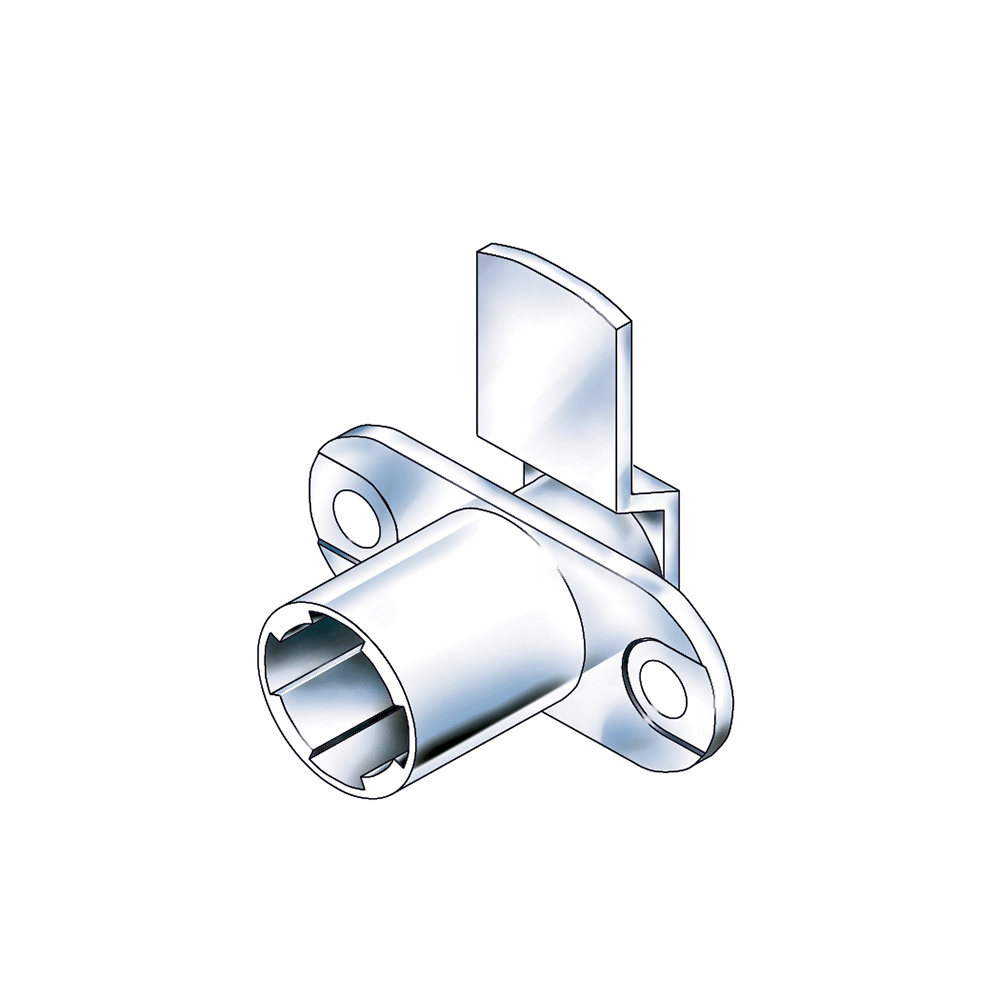

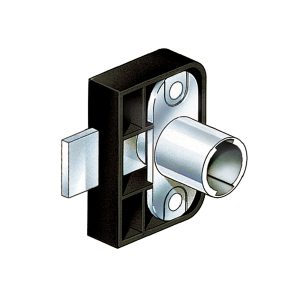

CompX provides 3D models: step and igs files that can be dropped into CAD drawings and can help plan placement and fitment for cabinet lock needs. CompX also provides 3D pdfs, which can be viewed prior to downloading CAD files.

The CompX dedicated engineering department is available to help discuss and plan projects, to help determine the best cabinet lock for the job, and if needed, to help design and develop a new cabinet lock for any unique situation. From idea to implementation to delivery, let the professional CompX engineers help get your project across the finish line.

Why Architects & Engineers Choose CompX

CompX Security Products has been manufacturing cabinet locks in the United States since 1903 under the four leading brands, CompX National, CompX Timberline, CompX Fort, and CompX Chicago. CompX’s goal is to provide the best and largest selection of cabinet locking solutions.

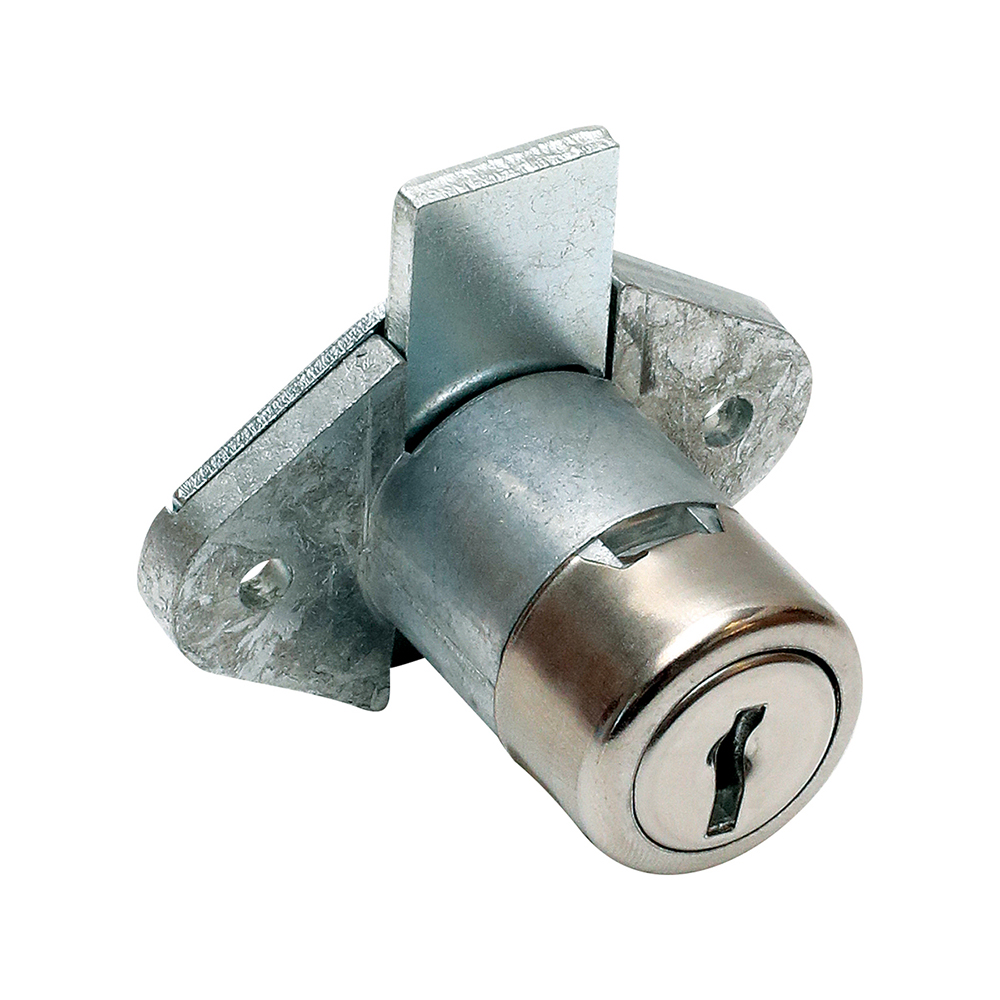

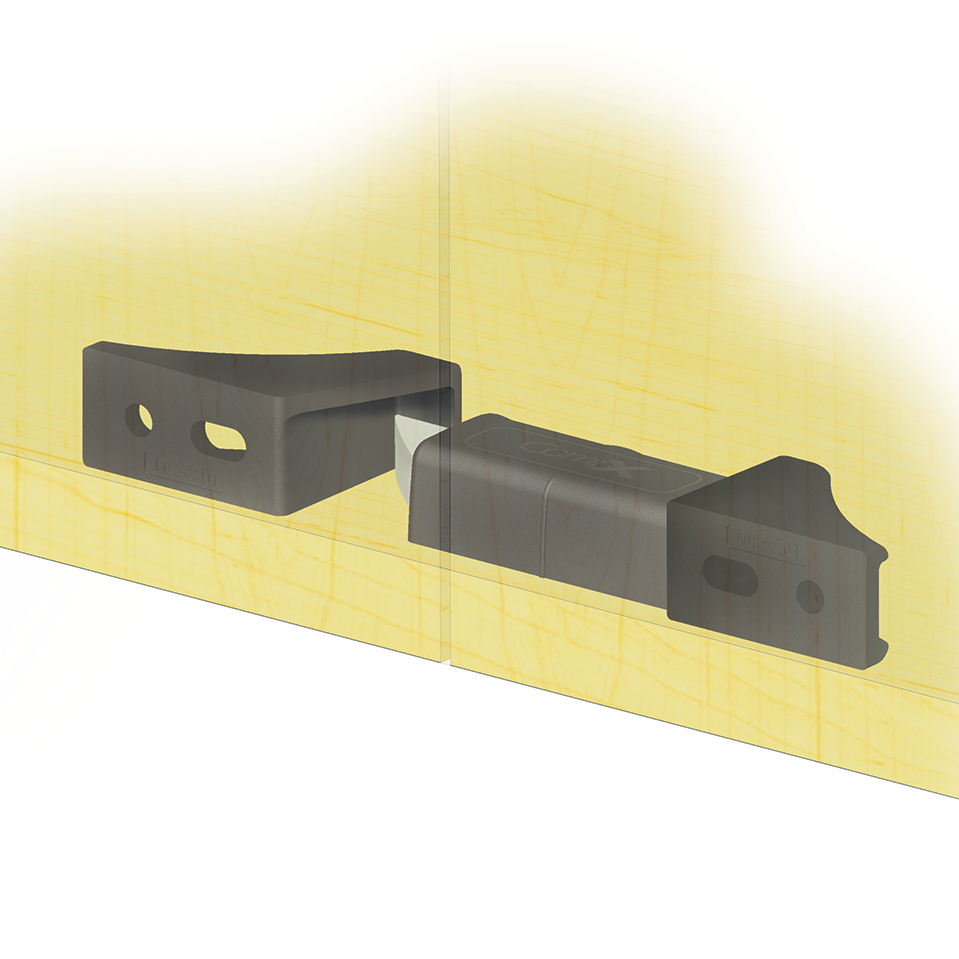

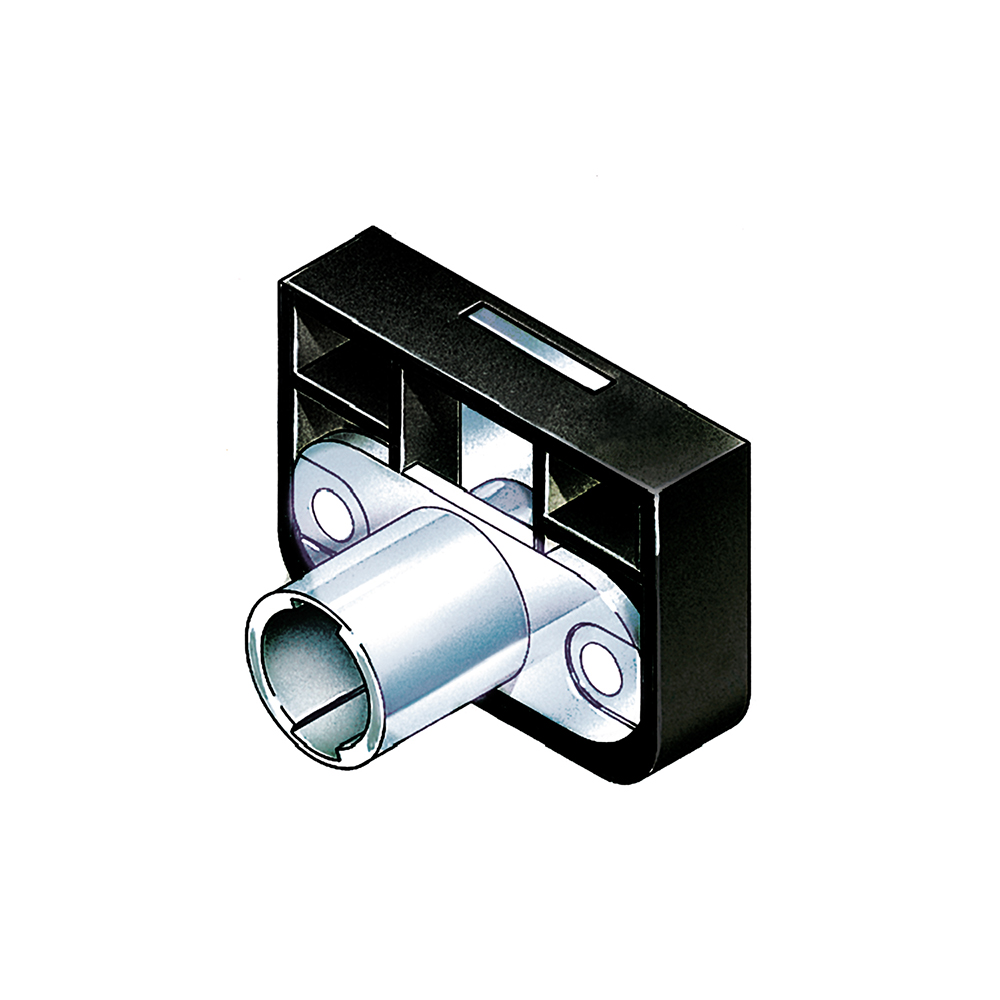

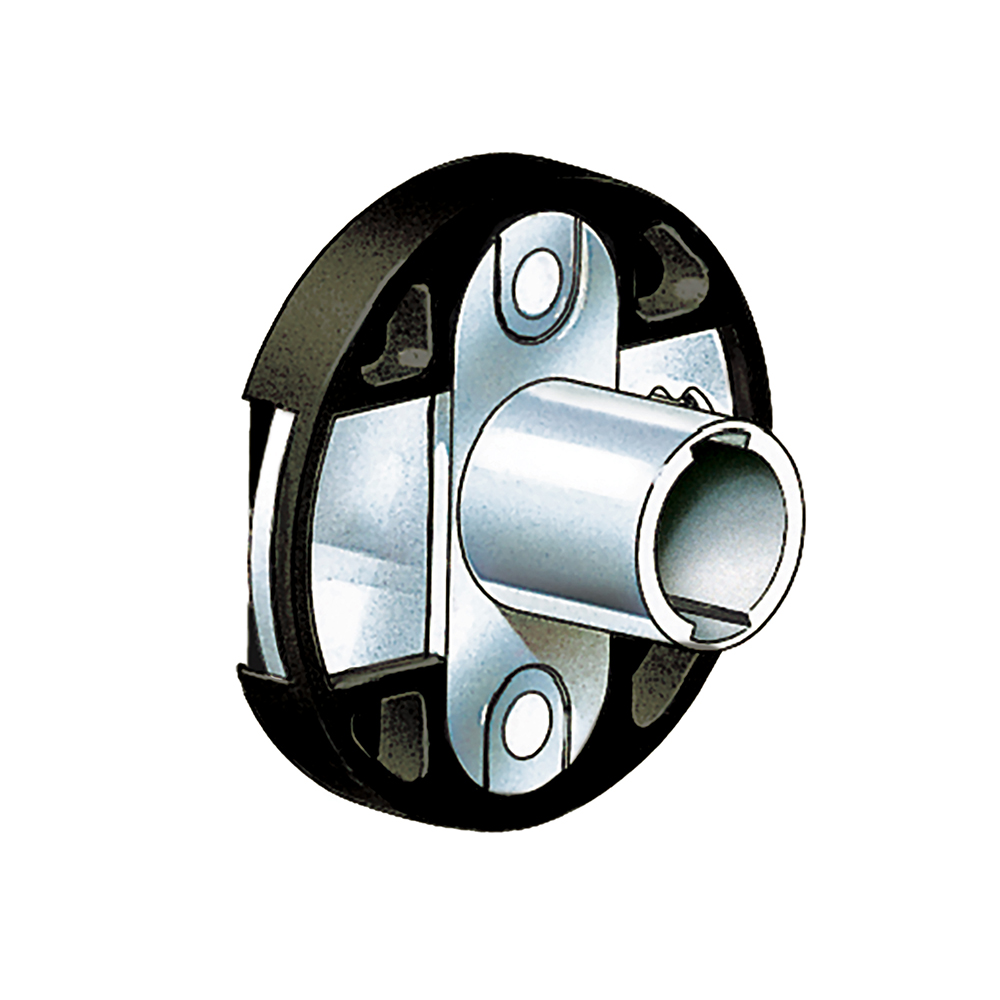

Known for innovation, quality and service, CompX Security Products provides the only BHMA Certified Grade 1 and Grade 2 Pin Tumbler Cabinet Locks available (ANSI/BHMA A156.11). All CompX branded five disc tumbler locks and anti-tip systems are designed to meet or exceed the current ANSI/BIFMA standards.

BHMA certified products - quality you can believe

Certified products provide purchasers with quality assurance. When you buy or specify certified products, you know that you are investing in products that are independently tested and graded to assure you that they will do their job.

The certification process consists of three steps:

- Rigorous testing

- Evidence of compliance

- Follow-up testing and auditing

Need BHMA certification *and* speed? CompXpress is the answer

All Grade 1 and Grade 2 BHMA certified locks are available in the CompXpress program & with Advantage PLUS+ feature.

CompXpress Program

Special Keyed Pin Tumbler Locks shipped next business day. Master keyed, keyed alike in groups. All locks are WI approved. Refer to the CompX National catalog for packaging and the Architectural Specification Guide for more information. 26D – dull chrome available in the CompXpress program. Other finishes ship in five business days from two locations: Rancho Cucamonga, CA & Mauldin, SC.

Advantage Plus Program

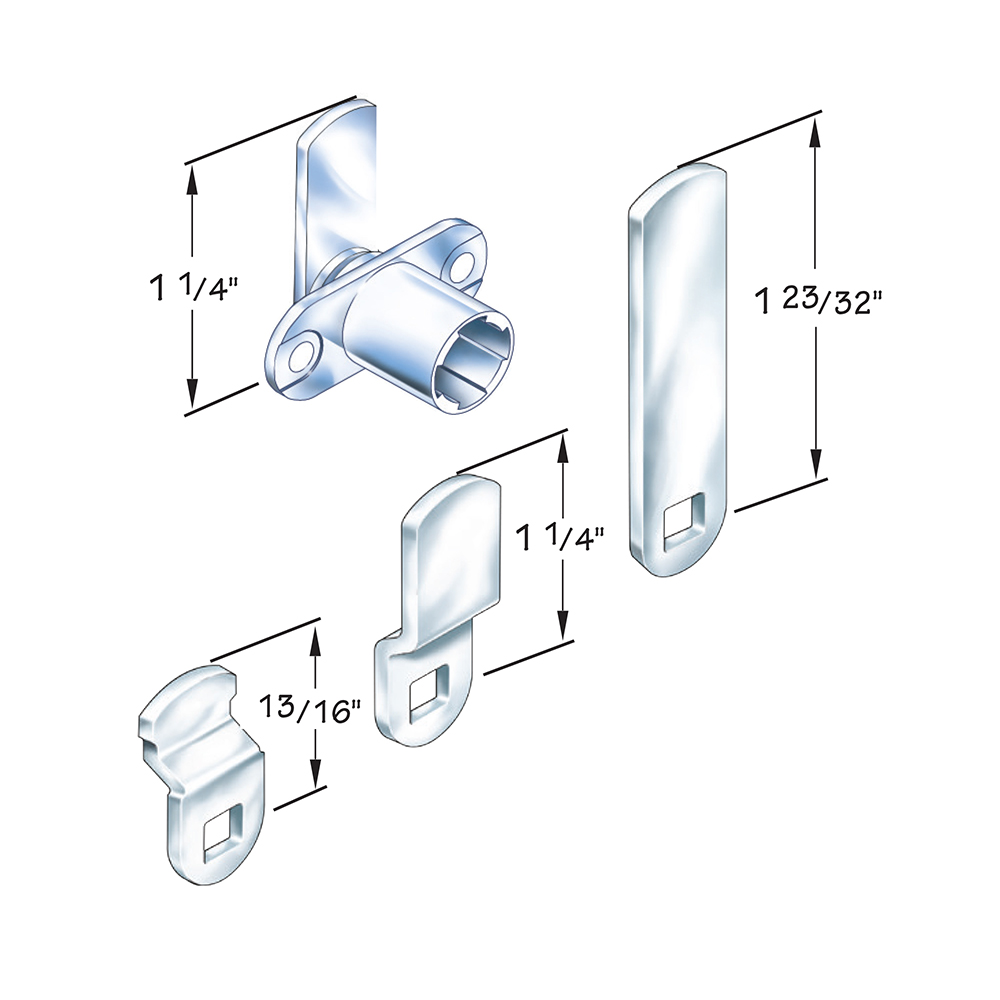

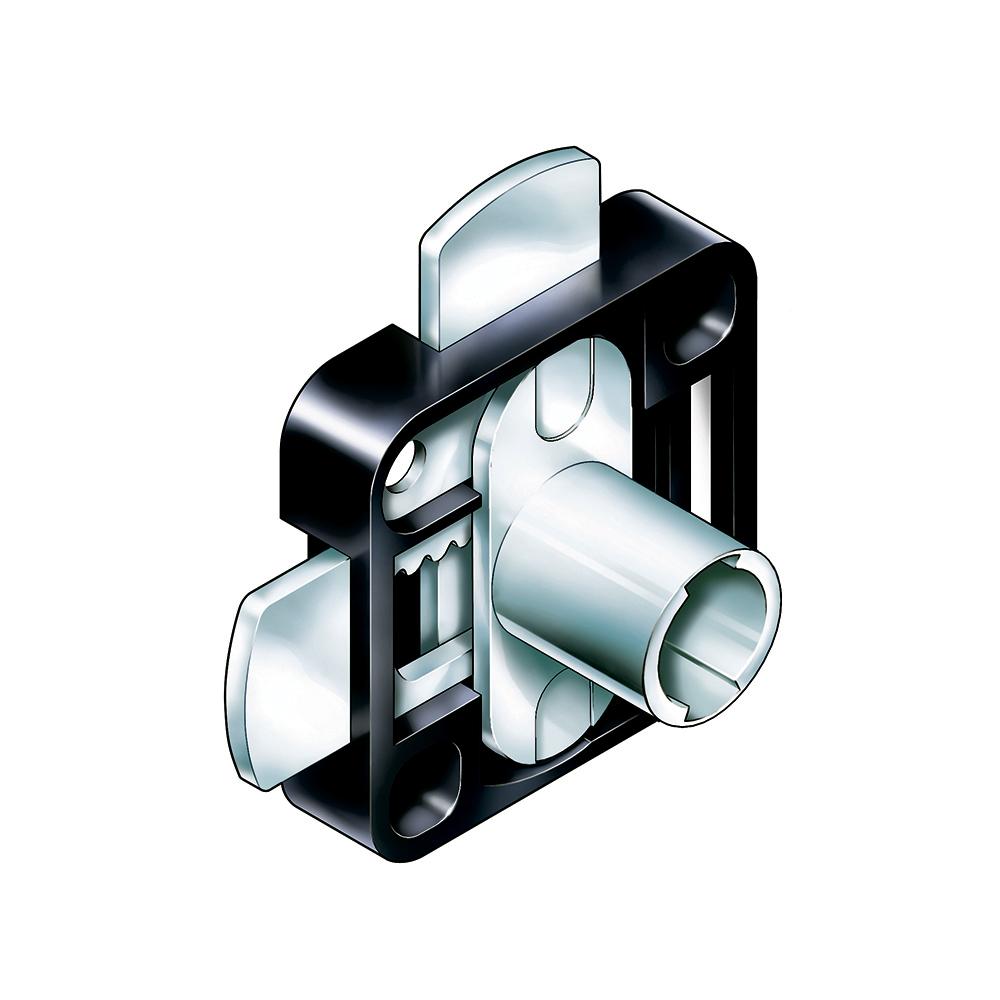

Allows users to remove the cylinder while the lock remains in place. NO mounting screws need to be removed. Simply use the 5/64″ Allen wrench from the back to remove the cylinder for re-keying or to replace the cylinder using the Replacement Cylinder program.

CompX takes pride in working lean and green - in America

Manufactured and assembled with pride in Mauldin, South Carolina, Grayslake, Illinois and Rancho Cucamonga, California, CompX’s domestically manufactured products exceed the two-part test requirements of the Buy American Act as defined in section 25.101 of the Act.

All water used in manufacturing facilities is treated by a polish filtration and ion exchange. This process triples containment of solutions to maximize protection to the environment. In addition, all scrap metals are collected and sent to recycling centers. Cardboard, batteries, light tubes and wood pallets are also bundled and shipped to recycling centers. CompX facilities are lean and green operations.